Luxury Cannabis Packaging

The cannabis industry is emerging, and we want to help you get the recognition you deserve in this increasingly saturated market. How can we help?

Differentiation is key.

Luxury cannabis packaging will set the tone for your brand. To sustain your advantage in a crowded market, it’s important to focus on creativity and innovation throughout every step of the process, starting with design. The purpose of your brand is to be memorable, which is accomplished by distinguishing your product from your competitors through labels, packaging, and accompanying inserts. Great design and production has the ability to generate meaningful first impressions that are meaningful for life.

There are several finishing techniques that can be added to your packaging to compliment the product you’re selling and enhance the packaging that your consumer first comes in contact with.

These include:

- Film Lamination

- Foil Stamping

- Die Cutting

- Embossing

- Spot UV and Matte Varnish

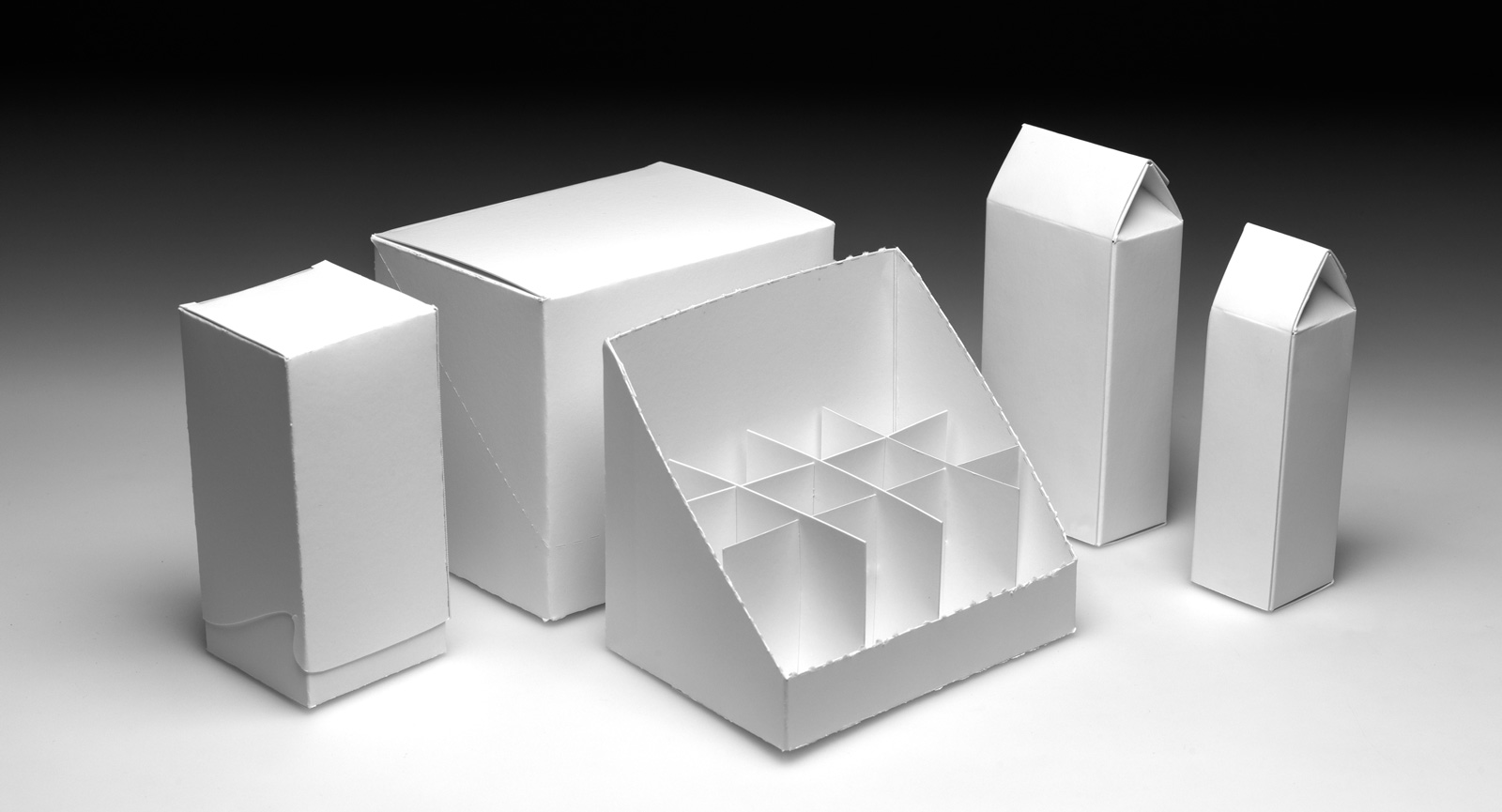

You don’t have to sacrifice design for sustainability. Paperboard packaging is durable and renewable, while holding on to its customizable features. Other than being visually appealing, paperboard folding cartons rank statistically higher in recycling and have minimal environmental impact. Paperboard also holds many benefits, such as being biodegradable and able to surpass tear strength requirements.

Sustainable packaging focuses on minimizing environmental harm. Plastic windows can be exchanged for “virtual windows” that show the product inside the packaging with a detailed graphic design.

Be Aware of Rules and Regulations

It’s important to stay up to date with new and revised packaging and labeling laws. Due to the constant shift in cannabis safety and regulation requirements, changes must be made to remain in compliance with state guidelines. Packaging must be tamper-proof, child-proof, and resealable. Labels must be easily readable, conspicuously placed, durable, and include the appropriate information as required by the state. Because cannabis label requirements change more frequently than most, digital print production remains an adaptable and affordable solution.

Cannabis Packaging Flexibility

In order to remain child-proof, cannabis packaging is tested to meet performance specifications created by the Consumer Product Safety Commission. The requirements included sealed, tight containment and one-time use package that are childproof.

A complete packaging line drives efficiency and simplifies the production process. From traditional printing methods for longer runs to digital printing for shorter runs, you have the ability to customize your production experience based on affordability and adaptability. Brilliant also offers graphic design, structural design and prototype testing.

Equipment Offerings:

- Digital Printing up to seven colors for short run and small multiple lot runs.

- Digital cutter and score machine for Prototypes or test run production.

- Digital UV

- Folder Gluer for production of Straight line, tuck top tuck bottom and auto-bottom boxes

- Die-cutter, Foil Stamp, Embossing

- Internal die-cutting die making